WE’RE A2L READY.

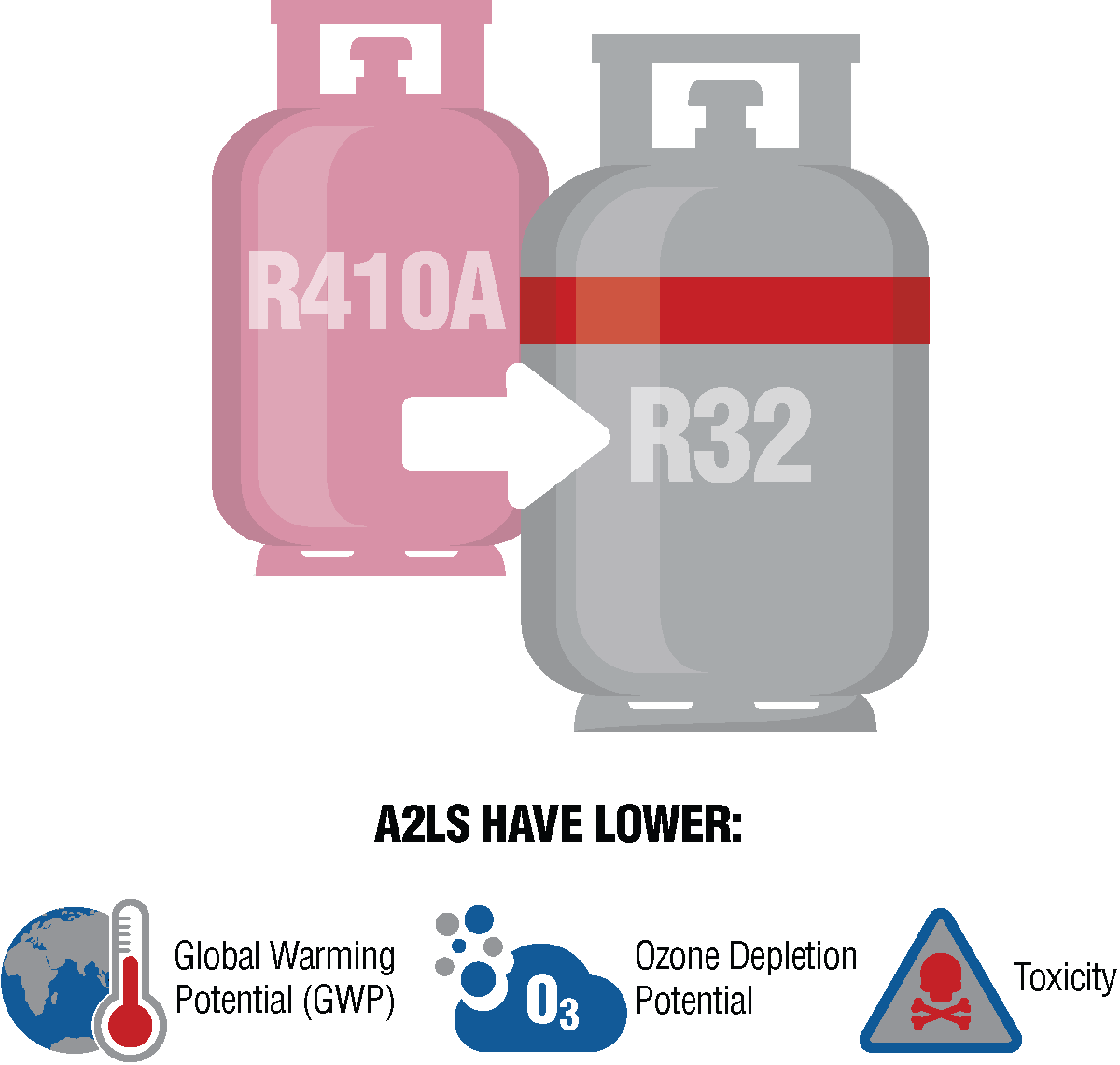

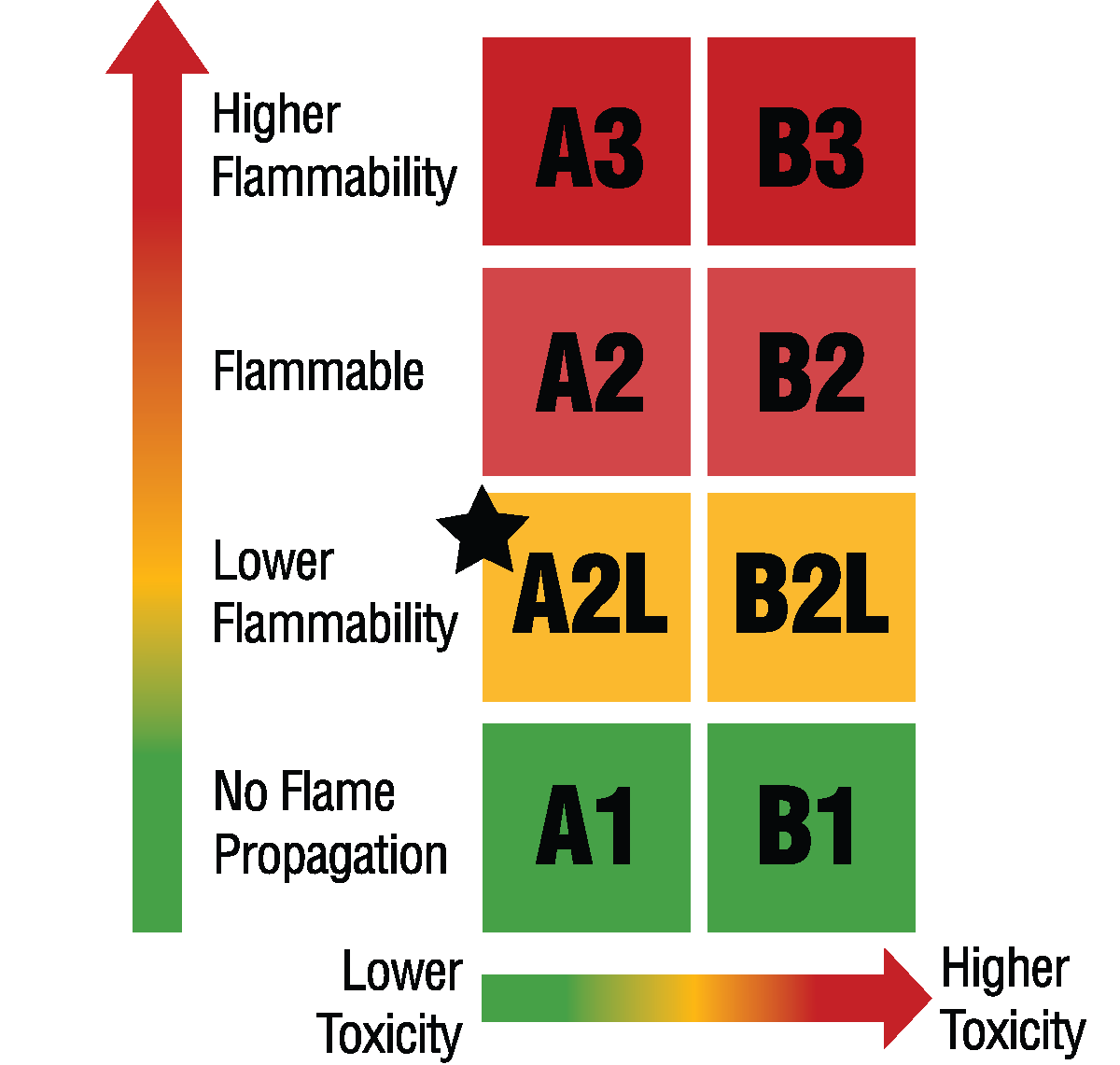

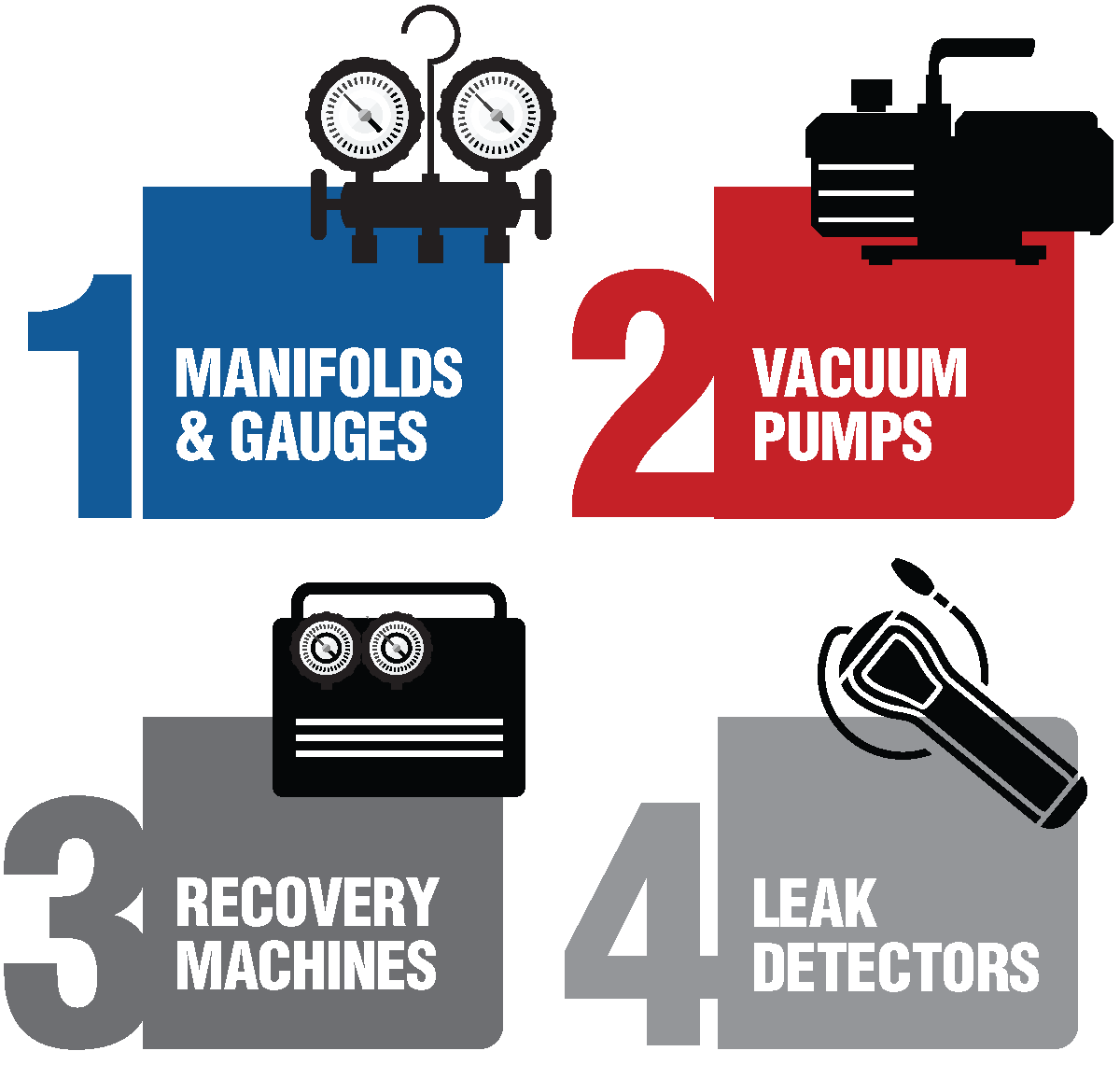

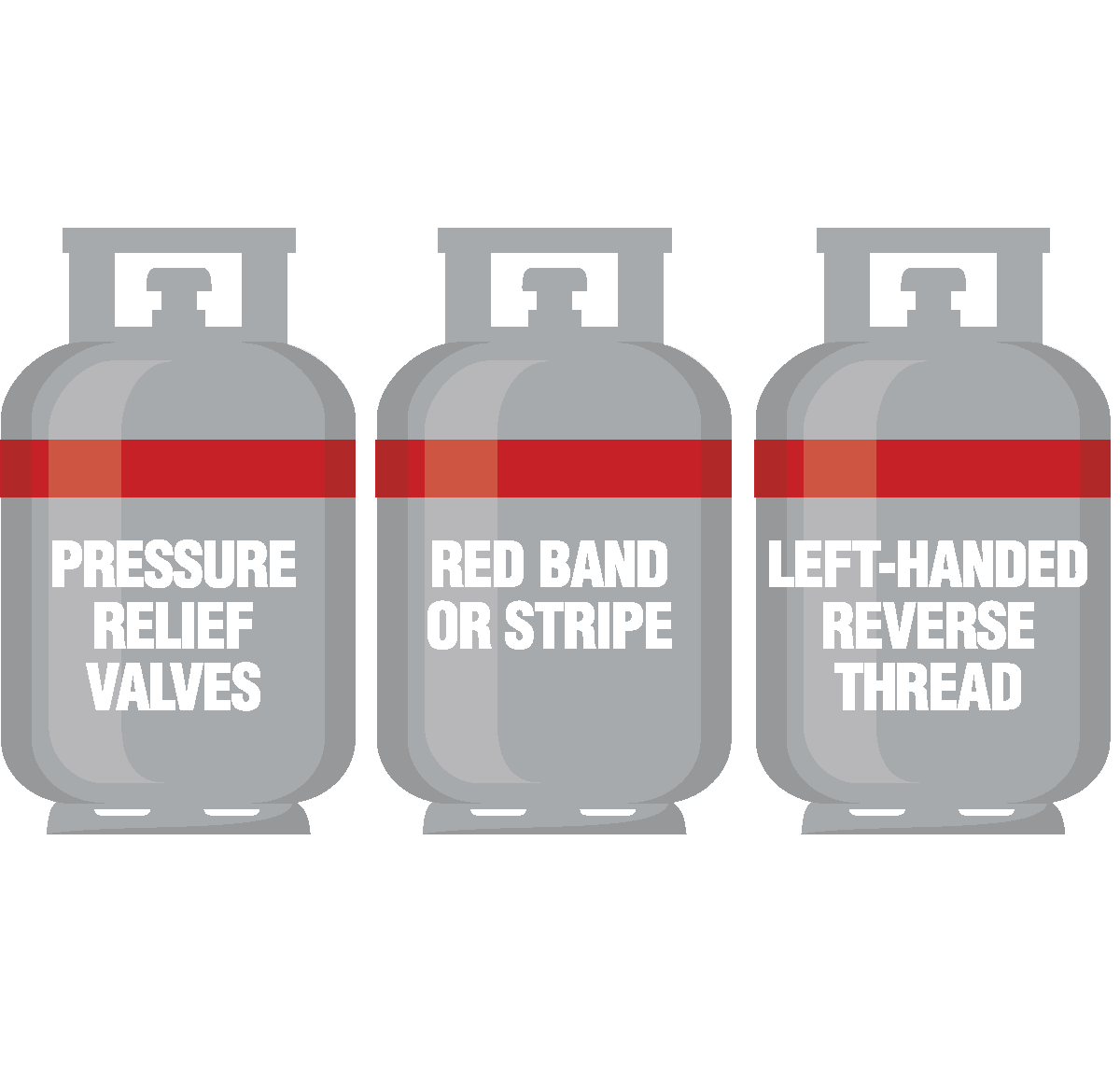

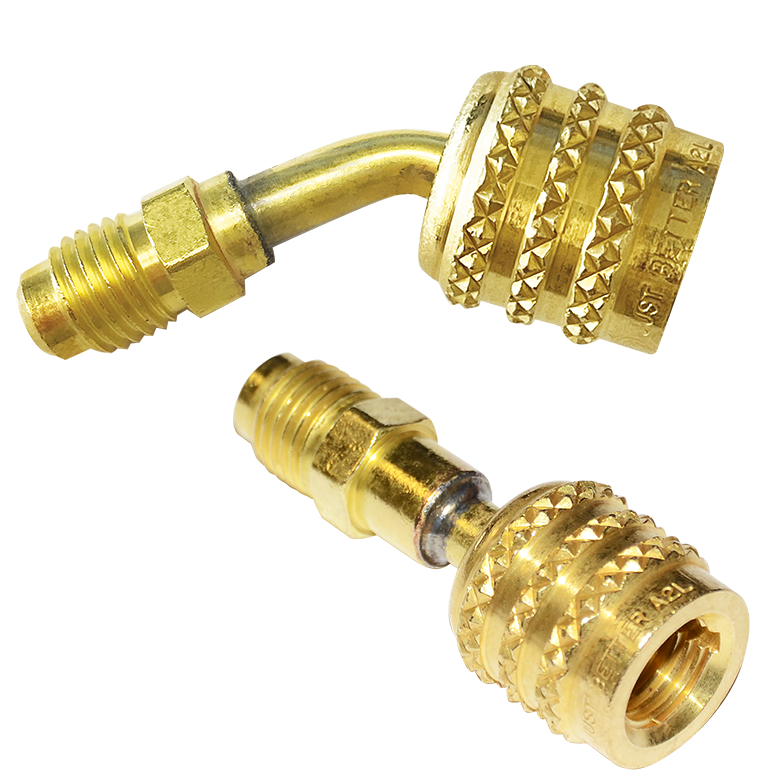

As the landscape of HVACR continues to evolve, the transition to mildly-flammable A2L refrigerants stands at the forefront of change. JB understands the importance of staying ahead of the curve. That’s why we’re proud to offer a comprehensive range of essential A2L-ready tools tailored to support our wholesale distributor partners and HVAC technicians through this transition seamlessly.

Navigating the switch to A2L refrigerants may seem daunting, but we’re here to help you with the tools and knowledge needed to thrive in this new era of refrigerants with confidence and expertise.

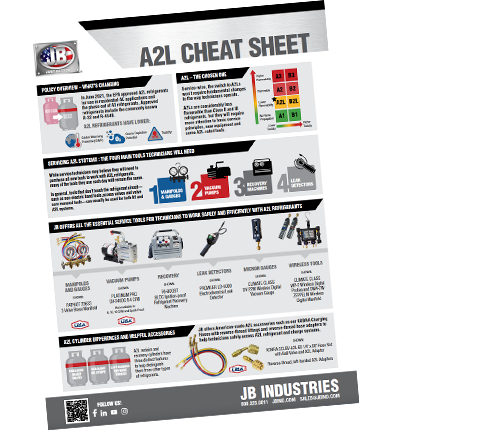

Enhance your team’s understanding of A2L refrigerants with our A2L Cheat Sheet. This one-page infographic is designed to streamline knowledge sharing on regulations, tools and best practices. Share it with your employees to ensure everyone stays informed and aligned with the industry transition. Download here.